In today’s manufacturing environment, efficiency is paramount. As industries strive to enhance productivity while maintaining quality, the integration of robotics has become a game-changer. Robotic welding and assembly applications play a crucial role in this transformation, allowing manufacturers to streamline their processes and achieve higher operational efficiency.

This article explores how the implementation of advanced robotics in welding and assembly not only boosts productivity but also contributes to significant cost savings and improved quality.

The Role of Robotics in Welding and Assembly

In modern manufacturing, robotics has become an integral component, revolutionizing traditional processes in welding and assembly through enhanced efficiency and precision.

Understanding Robotic Welding

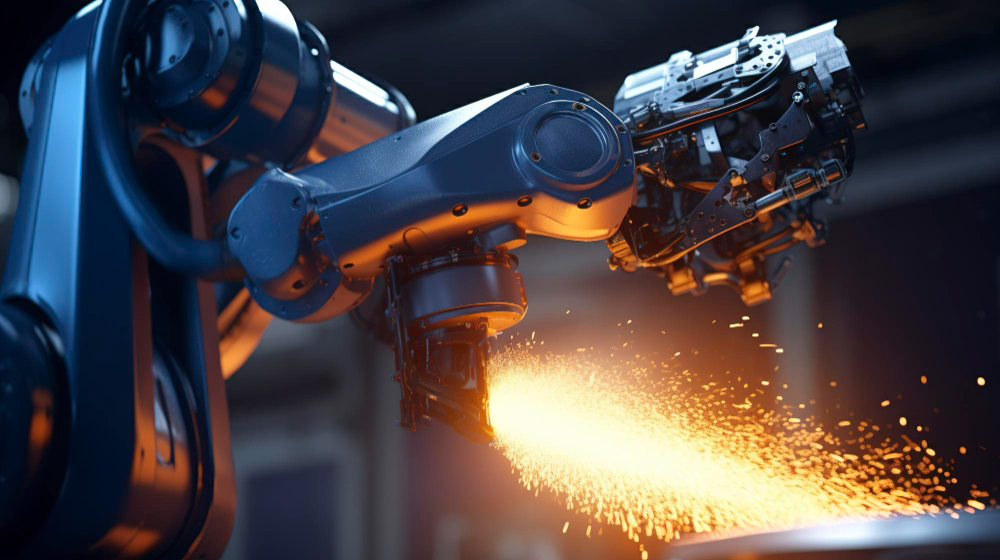

Robotic welding involves the use of automated systems equipped with welding tools to perform welding tasks. These systems consist of robotic arms, welding power sources, and control software. The most common types of robotic welding processes include Metal Inert Gas (MIG) welding, Tungsten Inert Gas (TIG) welding, and laser welding.

Robotic welding enhances operational efficiency by reducing cycle times and minimizing human error, allowing manufacturers to produce high-quality welds with speed and consistency.

Overview of Robotic Assembly

Robotic assembly refers to the automated process of assembling components into finished products. This can involve various tasks, such as fastening, inserting, and orienting parts. Robotic assembly systems significantly improve the speed and accuracy of production lines.

With their ability to adapt to different products and configurations, robotic assembly systems help manufacturers remain responsive to market demands while ensuring high levels of efficiency.

Benefits of Using Robotics in Welding and Assembly

The integration of robotics in welding and assembly processes offers numerous advantages that significantly enhance production efficiency and product quality.

Increased Precision and Quality

One of the primary advantages of using a robotic welder is the enhanced precision it brings to welding and assembly tasks. Robots are programmed to follow exact specifications, which reduces variability in performance. This consistency leads to fewer defects and higher-quality products.

Advanced sensors and monitoring systems further enhance this precision by enabling real-time adjustments, ensuring that welding parameters are always optimal. This reduces the risk of issues such as warping or misalignment, leading to a more reliable end product.

Enhanced Speed and Throughput

Robotics significantly accelerates production speed. Unlike human workers, robots can operate at high speeds without fatigue, which directly impacts throughput. Studies have shown that manufacturers using robotic systems can achieve production rates that are 50% higher than those relying solely on manual labor.

For example, in a factory utilizing robotic welding systems, reduced cycle times can lead to faster delivery of products to market. This increase in speed allows manufacturers to optimize their inventory management and reduce lead times, providing a competitive edge.

Flexibility and Adaptability

Robots are inherently flexible, and capable of performing a variety of tasks with minimal downtime. A robotic welding or assembly system can be reprogrammed to handle different products, enabling manufacturers to switch production lines quickly in response to changing market conditions.

This adaptability is crucial in industries where product variation is common. For instance, an automotive manufacturer can use the same robotic assembly line to produce different vehicle models without the need for significant reconfiguration, thus maximizing the utilization of their robotic systems.

Key Technologies Driving Efficiency

Advancements in technology are pivotal in enhancing the performance and capabilities of robotic welding and assembly systems, leading to greater efficiency and productivity.

Advanced Sensors and Vision Systems

The integration of advanced sensors and vision systems into robotic welding and assembly applications is revolutionizing the industry. These technologies enhance the robots’ ability to perform tasks with exceptional accuracy. For example, vision systems can guide a robotic welder to precisely locate and align parts before welding, ensuring optimal results.

Continuous monitoring through these sensors allows for real-time quality control. By detecting inconsistencies during the welding process, robots can adjust parameters accordingly, leading to fewer defects and improved overall product quality.

The Importance of Workforce Training

As robotics become increasingly integrated into manufacturing processes, effective workforce training is essential for maximizing the potential of these advanced systems.

Upskilling the Workforce

As robotics becomes more prevalent in manufacturing, there is a pressing need for workforce training. Employees must be equipped with the skills to operate, program, and maintain robotic systems. This upskilling not only prepares the workforce for collaboration with robots but also fosters a culture of innovation and adaptability within the organization.

Investing in training programs ensures that employees can leverage the full potential of robotic systems, leading to smoother integration and more efficient operations.

Promoting a Collaborative Environment

Encouraging a collaborative environment between human workers and robots is crucial for maximizing productivity. As collaborative robots (cobots) work alongside humans, understanding how to integrate their capabilities effectively is essential.

Training programs can emphasize teamwork, helping workers learn how to manage workflows that incorporate both human skills and robotic efficiency. This approach enhances productivity while maintaining a focus on workplace safety.

Conclusion

In conclusion, the integration of advanced robotics in welding and assembly applications has revolutionized the manufacturing industry, significantly boosting efficiency, precision, and adaptability. By automating these critical processes, companies can reduce cycle times, enhance product quality, and lower production costs.

Technologies such as advanced sensors, AI, and machine learning continue to drive these improvements, allowing robots to operate with greater accuracy and adaptability. Additionally, investing in workforce training ensures that human workers are equipped to collaborate effectively with robotic systems, fostering a harmonious and productive working environment.