Technology is reshaping global supply chains, transforming how goods move from manufacturers to consumers.

In the UK, this change has been driven by relatively recent issues, with almost half of the 5.6 million businesses experiencing an increase in disruptions in the last 12 months.

These disturbances have caused major frustrations for leaders and exposed weaknesses in traditional processes, spurring companies to adopt cutting-edge technologies to enhance resilience and efficiency.

- Artificial intelligence (AI) and machine learning (ML)

These tools enable us to make data-driven decisions. Retailers, for instance, are using predictive analytics to forecast demand with greater precision, helping to avoid overstocking or stockouts. Machine learning algorithms can analyse vast datasets, spotting patterns that would be nearly impossible for humans to detect.

- The Internet of Things (IoT)

By embedding sensors and smart devices in vehicles and warehouses, firms can monitor the movement and condition of products at every stage of the journey.

IoT-enabled shipping containers provide real-time insights into the location of cargo, allowing organisations to track deliveries with unprecedented accuracy. Having sight of this information can prevent delays, reduce losses and boost customer satisfaction.

- Blockchains

Blockchain technology is revolutionising supply chains by enhancing transparency and security. This decentralised digital ledger allows all parties involved to share and verify data, without the need for intermediaries.

One key benefit is its ability to provide an immutable record of transactions, which is particularly valuable in industries such as pharmaceuticals and food, where traceability is paramount.

By lowering the risk of fraud and improving the visibility of information, blockchain is growing trust between corporations and their customers, as well as between suppliers and buyers.

- Automation and robotics

Automation and robotics are rapidly transforming the warehousing and distribution aspects. Machines are now capable of handling tasks such as picking, packing and sorting with speed and precision. These help businesses process orders more efficiently, decreasing labour costs and minimising errors.

UK-based retailer Ocado is at the forefront of this revolution, using innovative systems in its automated warehouses to fulfil online food orders. By integrating these into their operations, companies can increase productivity and adapt more quickly to changes.

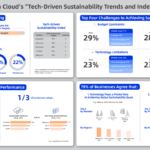

- Sustainable supply chains

From energy management systems to electric cars or vans, organisations can now reduce their carbon footprint while maintaining productivity.

Retailers like Tesco are adopting electric vehicles for their delivery fleets and optimising drop-off routes to cut both emissions and expenses. Moreover, there’s a focus on verifying the sourcing of goods, ensuring that everything sold is ethically produced and environmentally friendly.

As consumers demand additional transparency regarding the eco-friendliness of the items they buy, technology will play a crucial role in helping firms meet these expectations while preserving a competitive edge.